Business

General Motors will develop a North American materials processing factory for Ultium EV batteries

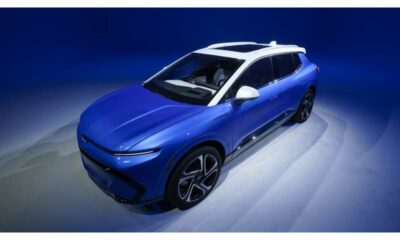

General Motors (GM) declared a joint endeavor close by POSCO Chemical to raise a new factory in North America to process Cathode Active Material (CAM). CAM will be essential to GM’s production of its proprietary Ultium EV batteries, as the legacy automaker hopes to build up a bigger presence in US EV production.

General Motors is a household name in automotive production that presently hopes to move its 113-year history of combustion toward an all-electric future. A simple year prior, GM pledged to deliver 30 new EVs by 2025, 66% of which will be accessible to US consumers.

The organization has since divulged forthcoming EVs like the GMC Hummer EV, Cadillac Lyriq, and a Chevy Silverado EV, albeit none have seen deliveries yet. A gigantic factor in GM’s speed increase toward EV adoption is its Ultium battery technology which is being used in its vehicles as well as electric locomotives.

Last May, GM affirmed a $2.3 billion investment with LG Energy Solution to assemble a gigafactory for EV batteries in Tennessee. This was followed by extra investments from the organization in June to additionally speed up EV production, including two extra GM plants for EV batteries by mid-decade.

With goals to restrict supply chains and bring both work and EV production stateside, GM reported an investment and commercial collaboration with Controlled Thermal Resources (CTR) to get cheaper lithium in the US.

Together with the assistance of POSCO Chemical, GM hopes to handle the materials for its EV batteries locally too, through a new North American facility.

The declaration came using an official statement from GM today close by restricted details and brief statements from both the automaker and POSCO Chemical.

Doug Parks, GM executive VP, Global Product Development, Purchasing and Supply Chain (say that ten times fast), talked about the new joint venture with POSCO.

The TBD North American facility will be focused on processing Cathode Active Material (CAM). As per GM, CAM is the key material that represents generally 40% of the total cost of every one of its EV batteries.

GM stated that both parties intend to sign a definitive agreement soon – the new material processing facility for EV batteries is relied upon to open its doors in 2024. The location will be declared at a later date.

-

Business2 weeks ago

Business2 weeks agoNayef Doleh Examines International Humanitarian Fundraising Strategies

-

Business3 weeks ago

Business3 weeks agoHow Black Banx is Redefining Global Banking Strategies in 2025

-

Business2 weeks ago

Business2 weeks agoHow to fill MSME Form 1? Step-by-Step Guide

-

Tech4 weeks ago

Tech4 weeks agoHow to Switch Between Microsoft Teams and Skype, How To Export Messages, Files, and Contacts from Skype Before It Shutting Down

-

Tech3 weeks ago

Tech3 weeks agoMicrosoft Teams to End SMS Messaging Feature Support for Android Phones and Switch to Phone Link App as Alternative

-

Education3 weeks ago

Education3 weeks agoSchool Of Odd Thinkers – Think Odd, Learn a lot, and Earn a lot

-

Education3 weeks ago

Education3 weeks agoThe Power of Differentiated Instruction: Patrick Granfar Discusses Its Impact on Student Learning

-

Education3 weeks ago

Education3 weeks agoJeffrey Laino Offers a Close Look at Literary Analysis Implementation